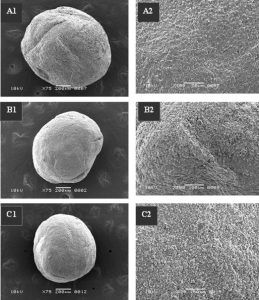

Immediate Release Pellets

Overview

Immediate release pellets are a type of pharmaceutical dosage form designed to release the active pharmaceutical ingredient (API) rapidly after administration. Unlike controlled or sustained release formulations, immediate release pellets dissolve quickly, allowing the medication to be absorbed into the bloodstream promptly to exert its therapeutic effect.

Key Features and Benefits

Rapid Onset of Action: Immediate release pellets ensure that the API is quickly available in the body, providing prompt relief from symptoms or quick therapeutic effects.

Enhanced Bioavailability: By facilitating rapid dissolution and absorption, immediate release pellets can improve the bioavailability of certain drugs, leading to more efficient treatment.

Patient Compliance: The quick action of immediate release pellets often results in faster relief, which can enhance patient satisfaction and compliance with the medication regimen.

Versatility in Administration: These pellets can be administered in various forms, such as encapsulated in capsules, compressed into tablets, or sprinkled on food, making them versatile and convenient for different patient needs.

Dose Uniformity: Pellets offer precise dosing and uniformity, ensuring that each dose contains an accurate amount of the active ingredient, which is crucial for maintaining consistent therapeutic effects.

Manufacturing Process

The production of immediate release pellets involves several critical steps to ensure quality and efficacy:

Drug Layering: The API is layered onto neutral cores (nonpareil seeds) using a binder solution in a fluid bed processor or a coating pan.

Drying: The layered pellets are dried to remove any residual solvents, ensuring stability and preventing degradation of the API.

Sizing: The dried pellets are sieved to achieve a uniform size distribution, which is essential for consistent dissolution rates.

Quality Control: The pellets undergo rigorous testing to ensure they meet the required specifications for content uniformity, dissolution rate, and stability.

| Aprepitant Pellets | 40% |

| Dabigatran Etexilate Mesylate Pellets | 41% |

| Donepezil HCl pellets | 15% |

| Dutasteride Pellets | 0.333% |

| Ebastine Pellets | 10% |

| Fenofibrate Nano DC Granules | 22.6% |

| Fenofibrate Pellets | 66.3%, 66.7% |

| Orlistat Pellets | 50% |

Applications

Extended or sustained release pellets are used in a wide range of therapeutic areas, including:

- Cardiovascular Drugs: To maintain steady blood pressure or heart rate control.

- Antidepressants: To provide consistent mood stabilization.

- Antidiabetics: For stable blood glucose management.

- Analgesics: For long-lasting pain relief.

- Antiepileptics: To ensure continuous seizure control.

Regulatory Considerations

The development and manufacturing of extended release pellets must comply with Good Manufacturing Practices (GMP) and regulatory guidelines from agencies such as the FDA, EMA, and other relevant authorities. This ensures the products are safe, effective, and of high quality.

Factory Address

Aamtoil Jathalia, Gazipur Bangladesh

Innoveau Chemicals Limited

Panaroma (4th Floor), 80 Satmosjid Road, Dhanmondi, Dhaka-1209, Bangladesh.

Phone:+880-2-58153109; +880-2-48116655,+880-2-48118964, +880-2-48119007

Fax- 880-2-9133296

- admin@innoveau.tech