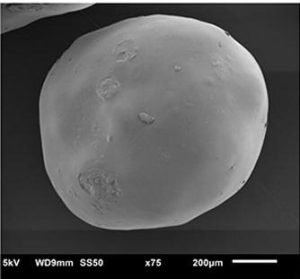

Blended Pellets

Overview

Blended pellets in pharmaceuticals refer to a formulation technique where multiple types of pellets, each with distinct release characteristics, are combined into a single dosage form. This approach allows for the simultaneous release of different active pharmaceutical ingredients (APIs) or varying release profiles of the same API, providing a versatile and effective means of drug delivery.

Key Features and Benefits

Customized Release Profiles: Blended pellets can be designed to provide immediate, delayed, and extended release of APIs within a single dosage form, tailored to meet specific therapeutic needs.

Combination Therapy: This method enables the incorporation of multiple drugs with different release kinetics, which is particularly beneficial for treating complex conditions requiring multi-drug regimens.

Improved Patient Compliance: By combining various release profiles in one dosage form, blended pellets reduce the need for multiple medications, simplifying the treatment regimen and improving patient adherence.

Enhanced Therapeutic Efficacy: The synchronized release of multiple APIs can enhance therapeutic outcomes by optimizing the timing and location of drug release.

Versatility in Formulation: Blended pellets can be encapsulated, compressed into tablets, or used in sachets, offering flexibility in product development and administration.

Manufacturing Process

The production of blended pellets involves several key steps to ensure the desired release characteristics and uniformity:

Pelletization: Different types of pellets are produced, each designed with specific release profiles such as immediate release, delayed release, or extended release. This is achieved through various coating and layering techniques using suitable polymers and excipients.

Blending: The individually prepared pellets are precisely measured and blended together. This process ensures that each dosage unit contains the correct proportions of each type of pellet to achieve the desired therapeutic effect.

Encapsulation or Tableting: The blended pellets are then either encapsulated into hard gelatin capsules or compressed into tablets, depending on the intended dosage form.

Quality Control: Rigorous testing is conducted to ensure uniformity, release profiles, and stability. This includes dissolution testing, content uniformity analysis, and stability studies.

| Ebastine IR + Pseudoephedrine HCl SR Pellets | 10mg + 120mg |

| Ferrous Fumarate + Folic Acid Pellets | 330mg + 1mg |

| Iron + Zinc + Vitamins B- complex + Folic Acid Pellets | Combinations |

| Memantine HCl SR + Donepezil HCl IR Pellets | 7mg + 10mg, 14 mg + 10 mg, 21 mg + 10 mg, 28 mg + 10 mg |

| Pseudoephedrine Sulphate SR + Fexofenadine HCl IR Pellets | 120mg + 60mg |

| Pseudoephedrine Sulphate SR + Loratadine IR Pellets | 120mg + 5mg |

| Tamsulosin HCl 0.267 % SR + Dutasteride 0.333% IR Pellets | 0.4mg + 0.5mg |

Applications

Blended pellets are used across a variety of therapeutic areas, including:

- Cardiovascular Diseases: Combining immediate and extended release antihypertensives to provide rapid onset and sustained control of blood pressure.

- Pain Management: Utilizing immediate release pellets for quick pain relief and extended release pellets for prolonged pain management.

- Gastroenterology: Combining different release profiles to optimize the treatment of gastrointestinal disorders such as irritable bowel syndrome or inflammatory bowel disease.

- Neurology: Blending immediate and sustained release anticonvulsants for steady seizure control.

Regulatory Considerations

The development and manufacturing of blended pellets must comply with Good Manufacturing Practices (GMP) and adhere to stringent regulatory guidelines set by health authorities such as the FDA, EMA, and other relevant bodies. This ensures that the products are safe, effective, and of high quality. Detailed documentation and testing are essential to demonstrate the consistency and reliability of the blended pellet formulations.

Factory Address

Aamtoil Jathalia, Gazipur Bangladesh

Innoveau Chemicals Limited

Panaroma (4th Floor), 80 Satmosjid Road, Dhanmondi, Dhaka-1209, Bangladesh.

Phone:+880-2-58153109; +880-2-48116655,+880-2-48118964, +880-2-48119007

Fax- 880-2-9133296

- admin@innoveau.tech